Enhancing Microbiology Precision through Airborne Contaminant Control in Sterile Environments

Microbiology research involves the study of sensitive samples, such as cell cultures, tissue samples, and microbial cultures, which require a sterile environment to prevent contamination. Contamination from external sources can introduce unintended microorganisms, skewing research data and undermining the validity of experiments.

A sterile environment with strict air quality control is crucial in microbiology laboratories. Airborne particles like dust, pollen, and microorganisms present a contamination risk. Air quality can vary depending on location and ventilation, with common air containing particles like mold spores, dust mites, and bacteria. In a lab setting, these contaminants can easily compromise sensitive microbiological samples and disrupt experimental integrity. Without filtration, airborne contaminants may easily enter laboratory environments and settle on surfaces, including experimental materials and equipment.

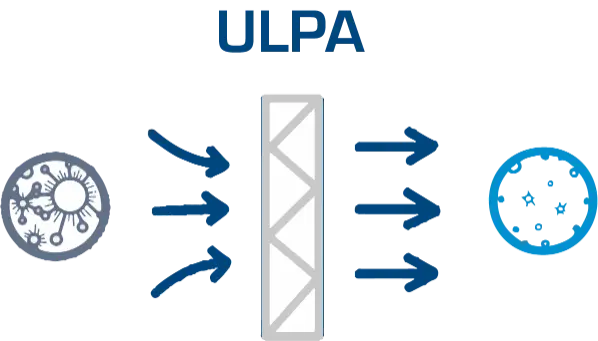

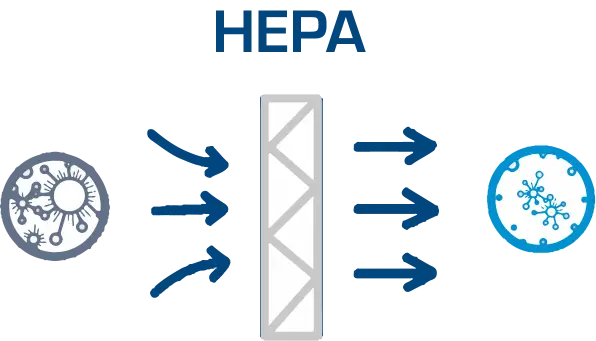

ULPA and HEPA Filter

Microbiology labs typically use specialized equipment to control and achieve required air cleanliness levels. A cleanroom or sterile facility provides a controlled environment where contaminants are minimized. Cleanrooms are equipped with special filters like ULPA (Ultra Low Particulate Air) or HEPA (High Efficiency Particulate Air) filters and follow stringent air quality protocols to maintain low particle levels.

This air filtration technology enables the cleanroom to maintain ISO standards for cleanliness, typically ISO Class 3 to 5, depending on the level of sterility required. Cleanrooms also incorporate airflow control systems that minimize particle movement. Laminar flow cabinets are essential parts of a sterile facility, creating work-area that support sample integrity by providing localized sterile airflow.

Esco is the world leader in premium laminar flow cabinets for the global industrial and life sciences market. They are the premium selection for discerning researchers and operators, offering a combination of value, high quality construction, low operating noise level, and wide product range to suit all budgets. Here is an overview of the key features and functionalities of Esco laminar flow cabinets:

- Equipped with ULPA filter which 10x filtration efficiency than HEPA filter and creates an ISO Class 3 work-zone instead of the industry-standard ISO Class 5

- Powered by latest generation DC ECM blower that is more efficient than legacy ECM and VFD motors, 70% energy savings compared to AC motor, provide stabile airflow and ISO Class 5 work zone during standby mode

- The world's quietest laminar flow cabinet. Reducing fatigue and improving work concentration with comfortable low noise emission at 55 Dba.

How Esco's Laminar Flow Cabinet Provide Sterile Work-zone

|

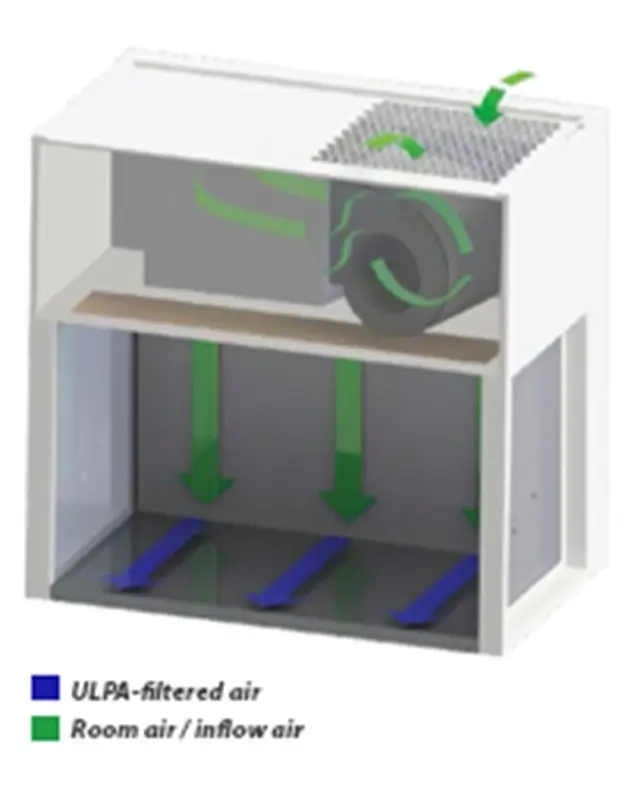

Horizontal Laminar Flow Cabinet provides a sterile work zone through a purified air that travels in a horizontal, unidirectional stream and leaves the main work chamber across the entire open front of the cabinet. |

|

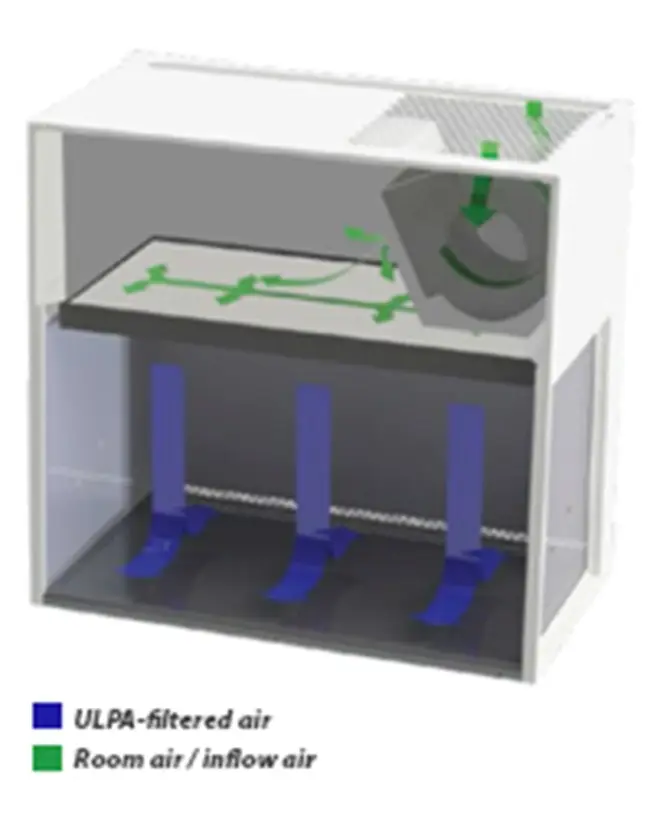

Vertical Laminar Flow Cabinet provides sample protection as purified air travels across the working zone of the cabinet in a vertical, unidirectional stream and leaves the main work chamber across the entire open front of the cabinet. Most vertical laminar flow benches also have perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |