I. Introduction

Biological Safety Cabinet is the primary engineering control that provides user, sample, and environment protection against biohazards. A biosafety cabinet’s airflow consists of an inflow barrier that prevents the accidental release of biohazards from the cabinet’s working area. It also has a downflow air that removes contaminants from the work zone, providing a sterile area for the samples.

A BSC should be selected based on the following criteria: type of work, classification of biohazards (Risk Group 1-4); personnel protection against exposure to radionuclides and volatile toxic chemicals; or a combination of these. The table below shows which BSCs are recommended for each type of protection.

Type of Protection | BSC Selection |

Personnel Protection, microorganisms in Risk Group 1-3 | Class I, Class II, Class III |

Personnel Protection, microorganisms in Risk Group 4, glove box laboratory | Class III |

Personnel Protection, microorganisms in Risk Group 4, suit laboratory | Class I, Class II |

Product Protection | Class II, Class III |

Volatile radionuclide/ chemical protection, re-circulated back to work zone | Class II Type B1, Class II Type A2 with ducting |

Volatile radionuclide/ chemical protection, no re-circulated back to work zone | Class I, Class II Type B2, Class III with ducting |

Source: Laboratory Biosafety Manual. 3rd ed (revised). Interim guidelines. World Health Organization. p52.

Esco Lifesciences is a world leader in biological safety cabinets, offering the industry’s widest product range, with thousands of installations in leading laboratories in more than 100 countries around the globe. Esco biological safety cabinets have earned more independent certifications in more countries, in more languages, than any other product, demonstrating our commitment to the industry’s best safety and quality.

Class I Biological Safety Cabinets

The Class I biosafety cabinet has the most basic and rudimentary design of all BSCs available today. It offers protection to the operator and the environment from exposure to biohazards and is suitable for work with microbiological agents assigned to biosafety levels 1, 2, and 3.

Class II Type A2 Biological Safety Cabinets

The Class II Type A2 biological safety cabinet is the most common Class II BSC. It is also the most common biosafety cabinet of all the different types available. It has a plenum from which 30% of air is exhausted, and 70% is re-circulated to the work area as the downflow. It protects the operator and the environment from exposure to biohazards and protects products from contaminated room air and cross-contamination.

If trace amounts of toxic chemicals are employed as an adjunct to microbiological processes, Type A cabinets should be exhaust-ducted.

Class II Type B2 Biological Safety Cabinets

A Class II Type B2 biological safety cabinet is designed to have no recirculation within the cabinet. The inflow and downflow air is exhausted after HEPA filtration to the external environment. Type B2 biosafety cabinets are suitable for work with toxic chemicals employed as an adjunct to microbiological processes as there is no recirculation. In theory, Type B2 BSCs may be considered as the safest of all Class II BSCs since the total exhaust feature acts as a fail-safe if the downflow and/or exhaust HEPA filtration system cease to function normally.

Class III Biological Safety Cabinet

The Class III biological safety cabinet provides an absolute level of safety, which cannot be attained with Class I and Class II biosafety cabinets. It is suitable for work with microbiological agents assigned to biosafety levels 1, 2, 3, and 4. It is frequently specified for work involving the most lethal biological hazards.

II. Biosafety Cabinet Guide to models

| Product | Model Code | Application | Classification | Certification | Construction | Control System | Accessories | Special Features | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Main body | Side Walls | Work zone | Blower | ||||||||

| AC1 | offers operator and environment protection against biohazards | Class I BSC | EN 12469 Compliance, SANS 12469 Compliance | E.G. Steel with Isocide™ antimicrobial coating | Tempered Glass | Single-piece SS worktop | Single Blower, DC ECM | Sentinel™ Gold Microprocessor control system | Secondary carbon filter, UV Door (with VHP In Port), Exhaust Ducting | Hinged window 90° opening for an easy workzone access | |

| Airstream® Class II Type A2 BSC- NSF Certified | AC2-NS | offers operator protection and environment protectio against biohazards while providing a sterile work zone to prevent contamination. | Class II Type A2 BSC | NSF 49 certified | Stainless Steel | Single-piece SS worktop | Single Blower, DC ECM | has an angled drain pan, option H2O2 port, Secondary Carbon Filter | Single blower for inflow and downflow. Energy-effecient and cost-effective | ||

| Airstream® Gen 3 Class II BSC- E series | AC2-E | Class II BSC | EN 12469 certified by PHE | Tempered Glass | Multi-piece SS worktop | Single Blower, DC ECM | Tempered glass increases visibility and prevents the operator from experiencing a “boxed-in” feeling | ||||

| Airstream® Gen 3 Class II BSC- S series | AC2-S | EN 12469 certified by PHE | Stainless Steel | Single-piece SS worktop | Single blower for inflow and downflow. Energy-effecient and cost-effective | ||||||

| Airstream® Gen 3 Class II BSC- D series | AC2-D | EN 12469 compliance | Stainless Steel | Single-piece SS worktop | Dual exhaust blower. DC ECM | Dual blowers for inflow and downflow. Reduntant system provides protection in case of fan failure | |||||

| Airstream® Gen 3 Class II BSC- G series | AC2-G | EN 12469 compliance | Tempered Glass | Multi-piece SS worktop | |||||||

| Airstream® Class II BSC TUV-Nord - E series | AC2-E-TU | Class II BSC | EN 12469 certified by TUV-Nord | Tempered Glass | Multi-piece SS worktop | Dual exhaust blower. DC ECM | VHP In Port, Exhaust Ducting | Unique stainless steel and glass hybrid wall increases visibility and prevents the operator from experiencing a “boxed-in” feeling, with coved corners for cleanability. | |||

| Airstream® Class II BSC TUV-Nord - S series | AC2-S-TU | Stainless Steel | Single-piece SS worktop | ||||||||

| Labculture® Class II Type A2 | LA2-A-E | Class II Type A2 BSC | NSF 49 certified, EN 12469, UL 61010, JIS K3800, CFDA YY-0569 | Stainless Steel | Single-piece SS worktop | Single Blower, DC ECM | Exhaust ducting | Energy-efficient, Ergonomic, Safe, Quiet, Most Certified | |||

| Airstream® Class II Type B2 | AB2 | Class II Type B2 BSC | NSF 49 compliance, EN 12469, CFDA YY-0569* *CFDA certification is exclusive to AB2 models sold in China | Stainless Steel | Single-piece SS worktop | Single EBM Blower | Sentinel™ Silver Microprocessor Control System | Secondary carbon filter, VHP In Port | Fail-safe system | ||

| Labculture® Class II Type B2 | LB2 | Class II Type B2 BSC | NSF 49 certified | Stainless Steel | Single-piece SS worktop | Single Blower, DC ECM | Sentinel™ Gold Microprocessor control system | Anti-blowback Valve, Pre-Filter | Energy efficient | ||

| Airstream® Class III BSC | AC3 | designed to be gas-tight to provides an absolute level of safety and protection against the most lethal biological hazards. | Class III BSC | EN 12469 Compliance | EG Steel with Isocide™ | Single-piece SS worktop | Double ECM Blower | Sentinel™ Silver Microprocessor Control System | Exhaust ducting | Exclusive dual exhaust filters provide >100,000 times better protection than single-stage designs | |

III. Must-have features of a BSC

Ensured containment of biohazards with Esco biological safety cabinets

Containment refers to the ability of the cabinet/enclosure to contain all hazardous particles inside the working space without any escape through the front of the cabinet. The most recognized way to test the containment of a biological safety cabinet in the field and after manufacture is through the KI-DISCUS test. It should be noted that a cabinet can pass all the airflow tests but still fail the containment test.

Esco Lifesciences is one of the few companies outside Europe with KI-DISCUS testing capabilities. In addition, all our biological safety cabinets have been type-tested and approved for containment using this method. Aside from KI-DISCUS, microbiological tests such as product and cross-contamination protection tests are also employed. These tests determine whether:

aerosols formed during microbiological applications can be effectively contained within the biosafety cabinet,

outside contaminants will not be able to enter the work zone,

aerosol contamination of other equipment can be effectively minimized.

Esco Biosafety Cabinet features:

Compliance with NSF49 or EN 12469 standards

Negative-pressured sidewalls to help prevent contaminants from escaping

Puncture-resistant metal plenum that resists tear and leaks for safer operation

ULPA or H14 filter that offers better filtration efficiency

Antimicrobial coating on surfaces that inhibits microbial growth and improve safety

DC-ECM blowers that offer a quieter operation, less heat output, and reduced energy costs

Angled-down and centered control system for operator’s convenience

An intuitive control system that displays the BSC’s parameters

Has audio and visual alarms for unsafe conditions such as airflow failure and sash alarm.

IV. Factors to Consider When Selecting a Biosafety Cabinet

Selection Based on Biosafety Level

Biosafety levels are measures to contain or isolate harmful infectious agents in a laboratory. For risk assessment of harmful agents, a Biological Safety Officer (BSO) and Institutional Biosafety Committees (IBC) may be of help. There are four biosafety levels:

Biosafety Level 1 is for undergraduate and secondary educational training, teaching laboratories, and for other laboratories that use microorganisms that are not pathogenic. Examples are Bacillus subtilis, Naegleria gruberi, and infectious canine hepatitis virus. Thus, BSL-1 containment only requires a sink for handwashing.

Biosafety Level 2 is appropriate for clinical, diagnostic, teaching, and other laboratories which deal with indigenous moderate-risk agents linked with human disease and is present in a community. Examples are the Hepatitis B virus, HIV, Salmonella, and Toxoplasma. These microorganisms may be used on the open bench as long as there is low production of aerosols. Hazards may be acquired through ingestion of or exposure of the mucous membrane from the microorganisms. Certain precautions should be taken in handling contaminated materials (i.e. sharp objects). Similarly, procedures involving aerosol should be undertaken in BSC or safety centrifuge cups. Personal protective equipment is also effective together with handwashing sinks and waste decontamination facilities.

Biosafety Level 3 applies to clinical, diagnostic, teaching, research, or production facilities handling indigenous or exotic agents with a potential for respiratory transmission that may be a cause for lethal infection. Examples are Mycobacterium tuberculosis, St. Louis Encephalitis virus, and Coxiella burnetii. Hazards may be acquired through autoinoculation, ingestion, and exposure to infectious aerosols. For containment, procedures should be done in BSC or a gas-tight aerosol generation chamber. Ventilation systems should also be appropriate to reduce the release of hazardous aerosols.

Biosafety Level 4 is appropriate for life-threatening hazardous agents or pathogens which may be spread through the aerosol route and has no available vaccine or therapy. Examples are Marburg or Congo-Crimean hemorrhagic fever. Hazards may be acquired through infectious aerosols, skin membrane exposure to hazardous droplets, and autoinoculation. To isolate the infectious agents completely, procedures should be done in Class III BSC or while in a full-body air-supplied positive-pressure personnel suit. The BSL-4 laboratory is located in an isolated complex with specialized ventilation and waste management systems. The entire operation of the laboratory should be handled by a laboratory director. A supplement to this will be the presence of trained laboratory personnel, safety measures/manuals, safety equipment, appropriate design of facilities, personal protective equipment, and biosafety level practices.

| Lethality | Medium | Cure | Ex | |

|---|---|---|---|---|

1 |

Safe |

Liquid |

Yes |

Bacillus subtilis |

2 |

Some |

Liquid |

Some |

HIV |

| 3 |

Serious |

Airborne |

Some |

TBC |

4 |

Extreme |

Airborne |

None |

Ebola |

Selection Based on the Filtration system

One of the most important components of a BSC is the filter. Currently, there are two kinds of filters that a biological safety cabinet utilizes:

- High-Efficiency Particulate Air (HEPA) filter that is 99.99% efficient at MPPS (typically at 0.30 micron).

- Ultra-Low Particulate Air (ULPA) filter that is 99.999% efficient at MPPS (typically at 0.12 micron).

ULPA filter is 10 times more efficient than the HEPA filter, thus a biosafety cabinet with an ULPA filter can provide better operator, product, and environmental protection.

Selection Based on Possibility to Block Inflow Grille

The operator and product protection are achieved through the air curtain created by both the inflow and downflow that goes into the front air grille. The user needs to select a BSC design that can prevent accidental blocking on the grille by operator arms or samples.

There are several ways to prevent the inflow grille blocking:

- Use a raised armrest.

- Put armrest above inflow grille

- Curve the inflow grille up (like an A-shape)

- Curve the inflow grille down (like a V-shape)

- Put the inflow grille lower than the front nosing of the cabinet and the work tray

Figure 1. Combination of raised armrest and curved inflow grille to prevent accidental blocking.

Selection Based on Airflow Alarm

There are different possibilities for alarms and control systems used by biosafety cabinets:

- Simple switches – the simplest control system with buttons to turn blower and lights on and off. Has audio and visual alarms to indicate airflow failure.

- Analog display – shows the airflow velocity and provides an overview on how far the current velocity is from the fail point.

- Digital microprocessor – displays the cabinet’s basic parameters such as airflow values to sash status and alarms. It has easy-to-use buttons for the cabinet’s operation and an LCD screen that enables the user to diagnose the status of the cabinet and program different features such as setting the experiment timer.

Selection Based on Front Window Mechanism, Material, and Angle

A biosafety cabinet has different window mechanisms wherein the user must select the most convenient type without compromising containment.

- Hinged window. The advantage is the ease to get the nominal aperture opening height because it is fixed. However, the operator must attach an optional front cover to cover the aperture when the UV light is on.

- Manual sash window. The operator must observe the correct nominal window opening height, as indicated by the guide mark and supported by the sash alarm. The sash window must be fully closed before the UV light is activated.

- Motorized sash window. This is similar to the manual sash window version, but the user just needs to press one or two buttons to move the window. Typically, two buttons are used for safety to ensure that both of the operator’s hands are outside the path of the traversing window.

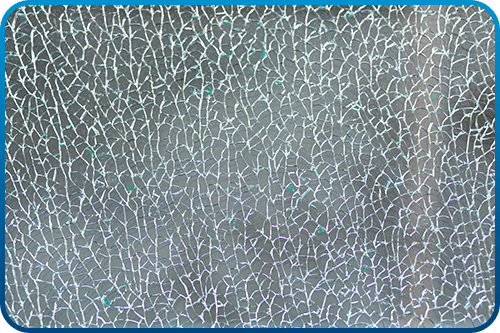

Figure 2: Sample photo of a smashed tempered glass sash.

Tempered glass or laminated safety glass are ideal materials for the sash of biosafety cabinets. Most tempered glasses are UV absorbing, clear, and will retain their shape when shattered to avoid any containment failure or accidents.

The sash can either be a vertical window or a sloped one. Vertical windows are easier to design but will provide eye strain to the operators. Modern biosafety cabinets have an angled front or sloping to provide better visibility while minimizing glares and reflections.

Selection Based on Work Trays

For safety, the BSC’s surface needs to be decontaminated before and after use, or after a large spillage occurs. Therefore, the cleanability factor plays an important role in selecting a Biosafety Cabinet:

-

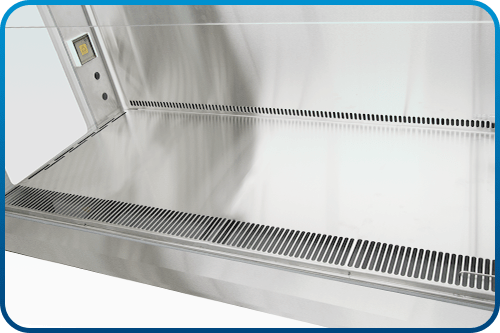

Single-piece work tray

A single-piece work tray has a recessed area that can help contain spillage. Due to its seamless design, spills will not drip down. However, it is more challenging to clean since it's heavier than the multi-piece trays.

Figure 3. Single-piece work tray of a biosafety cabinet.

-

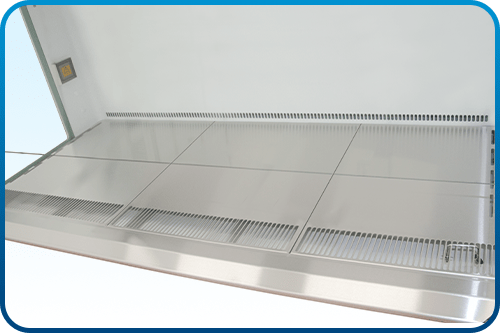

Multi-piece work tray

A divided work tray is lighter and easier to lift making cleaning more convenient. However, due to the segments, it cannot contain spills efficiently.

Figure 4. Divisions of a multi-piece work tray of a biosafety cabinet.

Selection Based on Ergonomics

Biosafety cabinets should be equipped with ergonomic features as this will provide comfort and increase productivity. Here are several features to consider when selecting a biosafety cabinet:

- Position and angle of the control panel - A control panel must be located in the middle of the cabinet where it is easier to see and reach. It is also important that the operator can access the control system whether they are standing up or sitting down.

- Lighting system - The light intensity of the cabinet shall exceed 1000 lux to provide a sufficient brightness in the work zone but with minimal glares for the user’s comfort.

- Low noise operation – It is ideal that the biosafety cabinet shall not exceed 67 dBA. This will prevent any distractions during operation.

- Position of the UV light – The UV lamp should not be placed directly on the operator’s line of sight to avoid eye irritation.

V. Safety Tips When Using Biosafety Cabinets

Tips on how to properly work in a Biosafety Cabinet

Biological Safety Cabinets are used for handling pathogenic samples or for applications requiring a sterile work zone. It protects the user from biohazards with an airflow barrier created by the inflow air. Simultaneously, samples inside the cabinet are also protected by downflow air that creates another airflow barrier. However, the effectiveness of the biosafety cabinet is only as good as how the operator uses it.

Here are several tips on how to work safely in your biosafety cabinet:

- Do not confuse biosafety cabinets with laminar flow cabinets.

- Do not use the cabinet for agents of extreme hazard.

- Do not operate the cabinet if any of the alarms are activated.

- A bunsen burner should not be used.

- Do not use the cabinet as a storage area.

- Proper cabinet location is critical.

- Always operate the unit continuously.

- Minimize disturbances to airflow barrier.

- The cabinet must be certified annually.

- Observe surface decontamination.

- Allow for purge cycles.

- Observe correct sash opening height.

- Only trained personnel should use the cabinet.

- Wear proper work attire.

- Work within the safe areas.

- Observe proper aseptic technique.